Acquisition in LEASING is available.

PURPOSE:

Laser complex MetalTec T-6016 is designed for laser processing of pipes and cutting pipes made of stainless, carbon steel, brass, aluminum and other metals of round, square, elliptical, hexagonal shape.</ p>

TYPES OF PROCESSED MATERIALS:

Metal pipes and profile pipes

TANK APPLICATIONS:

Metalworking, construction, mechanical engineering, etc.

PACKAGE:

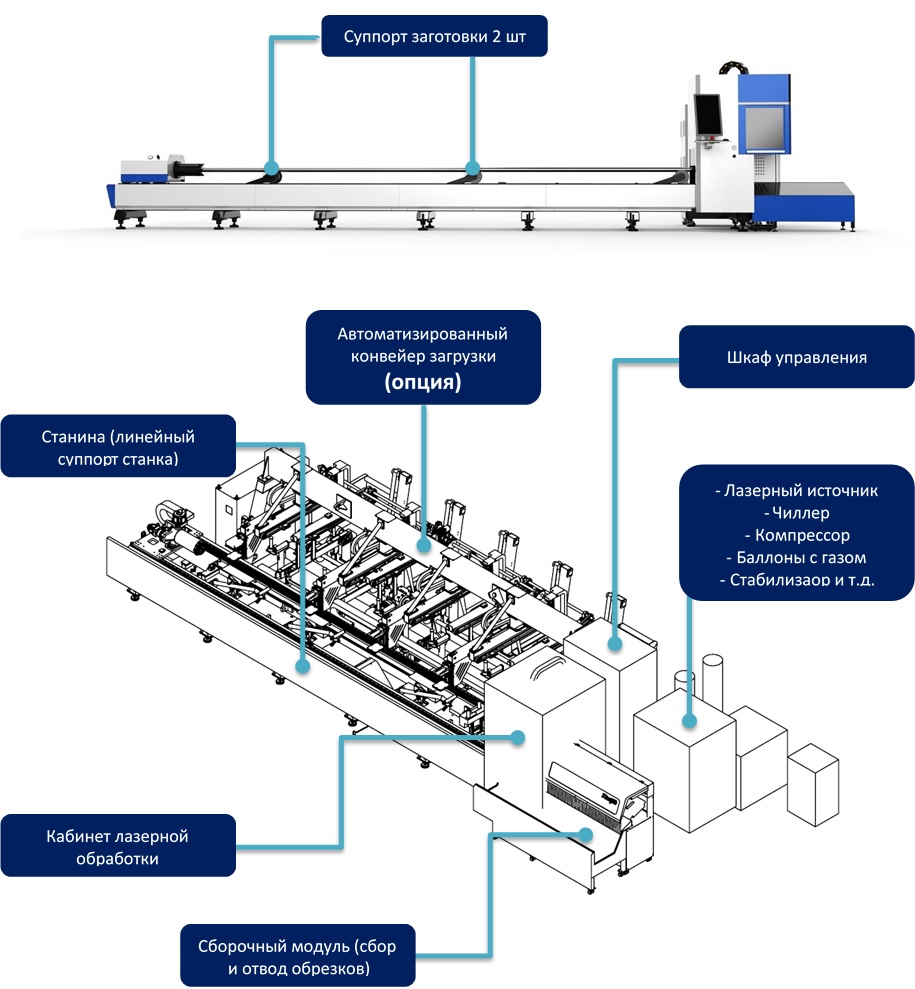

STRUCTURAL DIAGRAM OF THE MACHINE:

| Material | Thickness (mm) | Cutting speed (m/min) | Working gas | Gas pressure | Nozzle type | Focus Height |

| Carbon Steel | 1 | 22 | N2 | 12 | 1.5S | 0.5 |

| 3 | 3,6 | O2 | 0.6 | 1.0D | 1 | |

| 6 | 1,4 | 0.6 | 1.5D | 1 | ||

| 8 | 1,2 | 0.6 | 1.5D | 1 | ||

| 10 | 1 | 0.6 | 2.0D | 1 | ||

| 12 | 0.8 | 0.6 | 2.5D | 1 | ||

| 14 | 0.65 | 0.6 | 3.0D | 1 | ||

| 16 | 0.5 | 0.6 | 3.0D | 1 | ||

|

Stainless steel |

1 | 25 | N2 | 12 | 1.5S | 0.5 |

| 2 | 8 | 14 | 2.0S | 0.5 | ||

| 3 | 4,5 | 16 | 2.5S | 0.5 | ||

| 4,5 | 1.5 | 18 | 3.0S | 0.5 | ||

| 5.5 | 0.8 | 18 | 3.0S | 0.5 | ||

|

Aluminum |

1 | 18 | N2 | 12 | 1.5S | 0.5 |

| 2 | 6 | 14 | 2.0S | 0.5 | ||

| 3 | 2,5 | 15 | 2.5S | 0.5 | ||

| 4 | 0.8 | 17 | 3.0S | 0.5 | ||

|

Copper / Brass |

1 | 15 | N2 | 14 | 1.5S | 0.5 |

| 2 | 5 | 16 | 2.0S | 0.5 | ||

| 3 | 1.8 | 18 | 2.5S | 0.5 | ||

| 4 | 1 | 20 | 3.0S | 0.5 |

DESIGN FEATURES:

|

LASER SOURCE The machine is equipped with a laser source from MAXPHOTONICS (China). It is a world-famous and recognized leader in the field of laser production, which is confirmed by flawless and trouble-free operation. The company is one of the largest suppliers of lasers for various purposes around the world. The laser emitter is equipped with an air conditioning system for cooling electrical components. |

|

PNEUMATIC POWER GRIP High bearing capacity Full pneumatically driven rollers increase the chuck clamping reliability and its load-bearing capacity. |

|

HIGH PRECISION GEAR FOR WORKPIECE ROTATION High precision gearing effectively converts the smallest encoder pulses into radial motion. |

|

AUTOMATIC CALIPER SUPPORT Intelligent pipe support design that eliminates the problem of deflection when cutting long pipes. |

|

FULLY AUTOMATIC AIR CHUCKS FOR WORKPIECE FIXING Ensures stable clamping of various pipes and profiles.

|

|

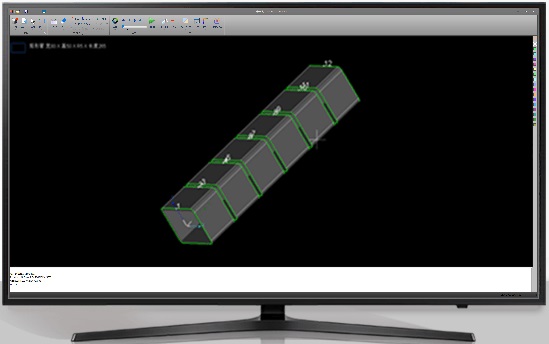

TUBEST LITE SOFTWARE TubesT Lite control system is a software system designed for laser cutting, which includes not only laser cutting process control, but also layer control, image processing, cutting process setting, machining path planning, cutting process simulation.< /p> |

|

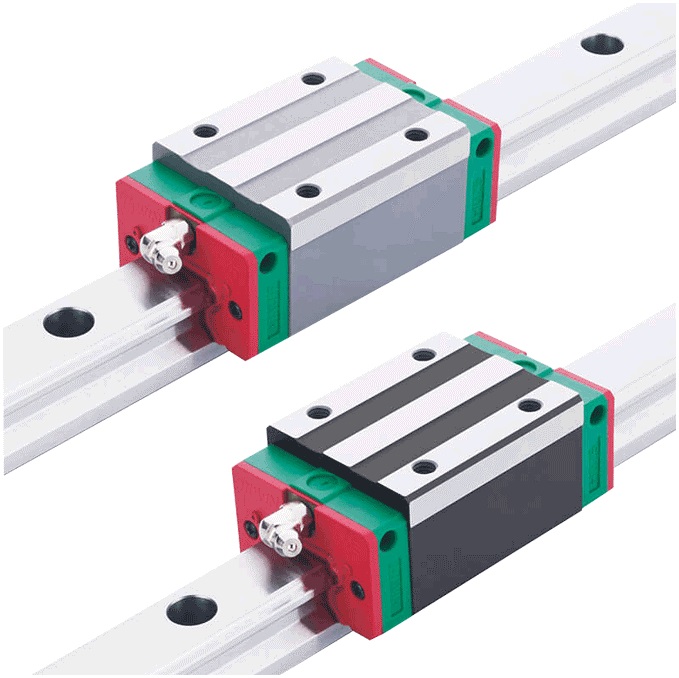

HIWIN HIWIN (TAIWAN) HIGH PRECISION LINEAR GUIDES OF INCREASED RIGIDITY The machine is equipped on all axes with square linear guides and carriages from HIWIN (Taiwan). Due to the increased stability and rigidity, they provide high accuracy of the portal movement along the axes. High processing accuracy and durability of the machine are achieved without loss of precision parameters. |

|

HIGH PRECISION BALL SCREWS TBI (TAIWAN) Due to the complete elimination of backlash, high-precision movement of the laser head along the Z axis is ensured when performing CNC processing of complex products with a high degree of accuracy. |

|

HELICATED RAIL ON THE AXIS To move along the X and Y axes, the machine uses a gear and a helical rack. This solution allows you to achieve high speed performance without loss of processing accuracy. |

|

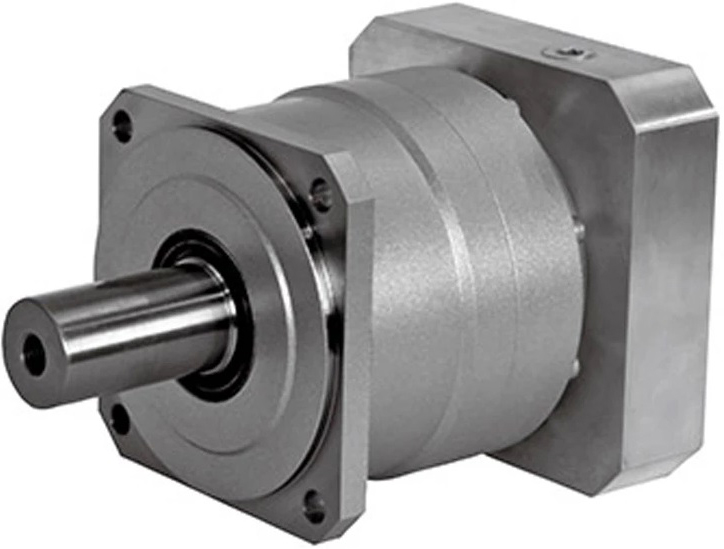

SHIMPO-NIDEC PLANETARY PRECISION GEARBOX (JAPAN) Advantages of the planetary gear:

|

|

METALTEC CH3000 LASER HEAD The machine is equipped with a METALTEC laser head, with an autonomous height controller that allows processing uneven surfaces, and a built-in water cooling system ensures stable operation of the laser head. Laser head with auto focus system. |

|

HIGH PRECISION FUJI SERVO MOTORS (JAPAN) To move along all axes, the machine package includes industrial servo motors FUJI (Japan), the accuracy and reliability of which ensures uninterrupted operation and consistently high quality of products. |

|

PNEUMATIC ELEMENTS SMC /AirTAc (JAPAN) The machine is equipped with a pneumatic system from a leading manufacturer: SMC / AirTac (Japan). |

|

HAN LI / S&A / HK INDUSTRIAL CHILLER Automatic chiller for cooling emitters of laser machines. The chiller allows you to continuously cool the laser system, preventing the laser source and laser head from overheating. The temperature is adjusted automatically. |

|

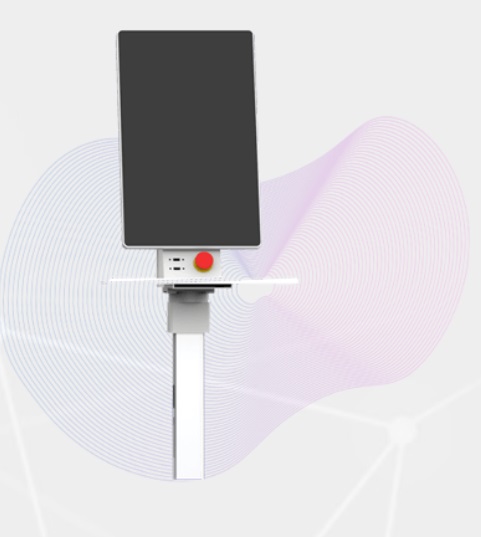

INDUSTRIAL LED DISPLAY High definition tempered glass screen. |